Not known Incorrect Statements About Plant Conveyors And Systems

Table of ContentsOur Plant Conveyors And Systems IdeasThings about Plant Conveyors And Systems7 Easy Facts About Plant Conveyors And Systems DescribedThe Plant Conveyors And Systems DiariesThe Basic Principles Of Plant Conveyors And Systems

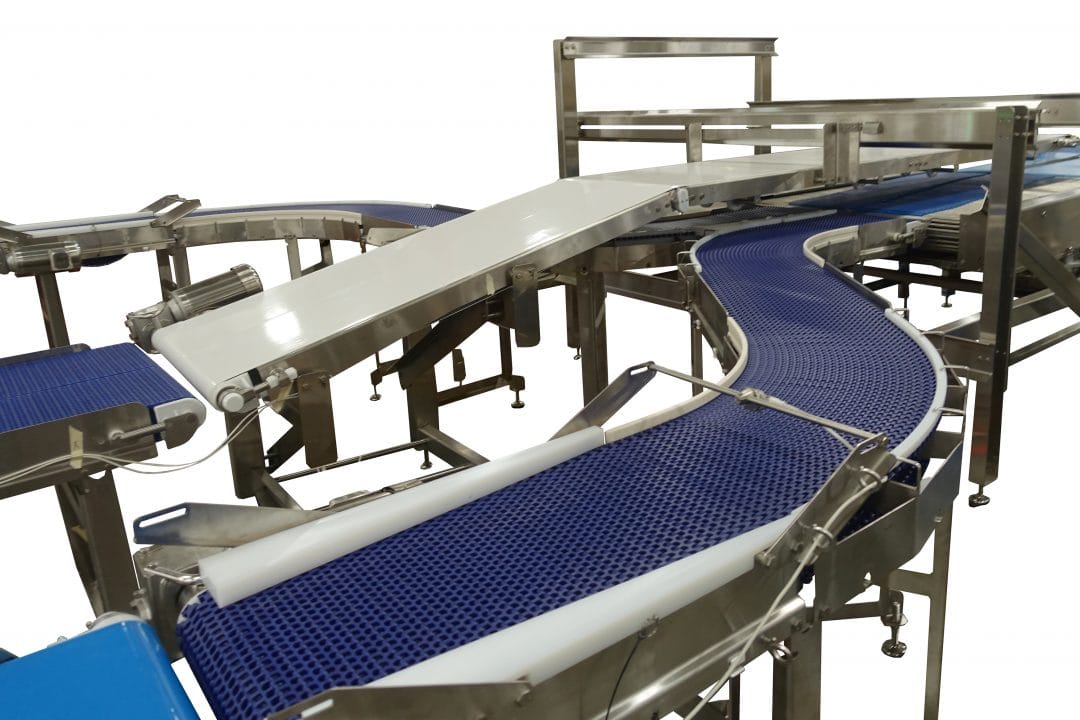

They usually have a system of gears run by an electric motor. Variable speed drives have actually come to be preferred for modern conveying considering that they permit changes of material flow. Safety: Conveyor systems are managed by the Occupational Security as well as Health And Wellness Administration (OSHA) as well as must fulfill federal government safety requirements. All conveyor manufacturers understand the policies and follow them.Belt Conveyors Belt conveyors are one of the most typical and also simplest form of conveyor as well as can have variable rates. They have a moving belt that hinges on a steel frame that supports the belt and also the materials being relocated. Ones that have a sustaining frame beneath are described as sliding style.

Gravity Roller Conveyors Gravity roller conveyors have a set of just as spaced rollers attached to a side frame. If a gravity roller conveyor is tilted or installed on an angle, materials move by gravity.

Chain Conveyors Chain conveyors can have 2 or numerous sets of chains that reach the base of things to be relocated - Plant Conveyors and Systems. The products hinge on the chains as they are moved. Chain driven conveyors are perfect for products with unequal lower surface areas or ones that are really heavy.

The Facts About Plant Conveyors And Systems Revealed

Due to the kinds of products chain conveyors move, they run really slowly. Motorized Roller Conveyors Motorized roller conveyors make use of motors, placed along the conveyor frame, to power uniformly spaced rollers. The style resembles a gravity conveyor with the addition of motors. The variety of motors is reliant on the lots to be relocated as well as the total layout of the system.

In some systems, there is a sensor that begins and also quits the motor to stay clear of items getting loaded with each other. Slat Conveyors Slat conveyors have the same design as chain conveyors with level slats connected to the chain. In some ways, they are comparable to belt conveyors with slats replacing the belt.

Open Track Conveyors - Open up track conveyors do not cover the track and usage I beams as the track. Chain Expenses Conveyors - Chain overhead conveyors make use of a constant powered chain that runs along a track.

In other styles where necklaces are not made use of, pusher dogs may be made use of to move trolleys along a second track positioned below the chain track. This sort of system is described as power and also complimentary. Monorail Conveyors Monorail communicating systems have providers to relocate products and are optimal for usage over cross countries.

Plant Conveyors And Systems - Truths

Monorail conveyors use the space over the production area. In some layouts, the providers lower to the level of manufacturing and after that rise, off the beaten track. Power as well as Free Conveyors Power and complimentary conveying systems are developed to move components through the manufacturing and also assembly procedure.

They quit at each terminal to be worked with and after that go on. Power and cost-free systems are an unique form of overhanging sharing system. The special layout of power and also free systems allows a product to be buffered along the sharing path, beginning and also stop automatically, as well as are very versatile and adjustable.

Upside down Conveyors Inverted conveyors are Bonuses floor placed and can be used as power as well as complimentary conveyors. They usually have a drive system that does not include a belt or chain. Paternoster Conveyors Paternoster conveyors are an upright communicating system that uses equal spaced tons providers attached to a chain drive, which relocates a constant loophole (Plant Conveyors and Systems).

9 Simple Techniques For Plant Conveyors And Systems

The chain can bending along the horizontal axis permitting it to make horizontal turns and also is qualified of making upright curves. The numerous kinds of twists and also transforms a COE makes allows it to be much more flexible than typical chain driven conveyors. Skid Conveyor Skid conveyors are another type of flooring mounted conveyor that relocates products on fixtures that have longitudinal runners called skids with travel being longitudinally and also transversely.

Skid conveyor systems are valued for the performance and also silent setting of transportation. The variants in skid visit site conveyor systems are due to the several elements and also control systems that can be consisted of. Rubbing Conveying System A friction read this article communicating system utilizes a motor to drive a friction wheel constructed from non metallic material to develop driving pressure.

Rubbing communicating systems are a risk-free alternative to power and also cost-free systems with the major benefit of running cleaner and also quieter. They have a flexible format, unit building and construction, easy speed altering, can conveniently be broadened, as well as low overall price. The main objective for rubbing conveying systems is to help with operations that have a high production price.

All About Plant Conveyors And Systems

Assistance System: The assistance system permits the belt to relocate efficiently. It is especially created to hold the moving product without sagging.